After a conference call in which the medical device giant announced an expanded use of metal 3D printing, Stryker has made even more progress in bringing 3D printed implants to market. The company has just announced 510(k) clearance from the FDA for their Tritanium PL Posterior Lumbar Cage, a device aimed at encouraging spinal fixation in patients with degenerative disc disease.

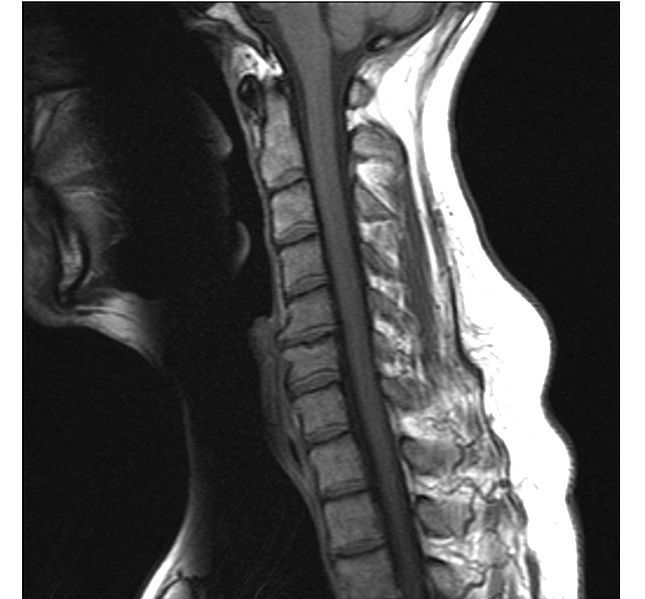

Stryker’s Tritanium is described as a porous titanium material designed for improved bone growth, necessary for securing a spinal implant in place over time. This patented material is essential for the company’s Tritanium PL Posterior Lumbar Cage, used to treat degenerative disc disease, grade I spondylolisthesis and degenerative scoliosis. Because the device is 3D printed, Stryker is able to offer the lumbar cage in a variety of widths, lengths, heights, and lordotic angles. And, through the use of large lateral windows and an open architecture, fusion of the cage with the body can be observed in CT scans and X-rays. And increased surface area, achieved through serrations within the cage, allow for bidirectional fixation

Stryker’s Tritanium is described as a porous titanium material designed for improved bone growth, necessary for securing a spinal implant in place over time. This patented material is essential for the company’s Tritanium PL Posterior Lumbar Cage, used to treat degenerative disc disease, grade I spondylolisthesis and degenerative scoliosis. Because the device is 3D printed, Stryker is able to offer the lumbar cage in a variety of widths, lengths, heights, and lordotic angles. And, through the use of large lateral windows and an open architecture, fusion of the cage with the body can be observed in CT scans and X-rays. And increased surface area, achieved through serrations within the cage, allow for bidirectional fixation

Brad Paddock, President of the Spine Division at Stryker, says of the product, “This is an exciting time for Stryker. We are committed to offering a full range of innovative spinal products that allow surgeons to help their patients return to a more active lifestyle. Our advanced 3D additive manufacturing capabilities allow us to precisely manufacture the porous structures of Tritanium and specific implant geometries. We are pleased to bring this technology to our spine surgeon community and their patients.”

The device will be made available to orthopaedic and neurosurgeons in the second quarter of 2016. This, along with news from Materialise about its new inPrint software and the ongoing clinical trial of 3D printed pre-surgical models, suggests that 2016 may just be the year that 3D printing becomes mainstream in the medical field.